Airborne Wind Energy: Flying Wind Turbines?

Introduction to Airborne Wind Energy

The global population is projected to increase to nearly 10 billion people by 2050 (1), and consequently so too will the demand for energy in order to sustain such a large population. While energy production via the use of heavily polluting non-renewable hydrocarbons is unlikely to be phased out completely in such a short time frame, the proliferation of renewable energy, including wind energy, holds the potential to be instrumental in cutting down greenhouse gas emissions to meet the Paris Agreement and limiting global temperature increase to less than 1.5 °C above preindustrial levels.

It has been suggested that the multiple oil crises in the 1970s were the catalyst of modern development of renewable energy, with aimed to improve energy security by reducing dependency on crude oil (2). More recently, the advancement of computational modelling as well as the state of the climate crisis have caused a resurgence in R&D into wind energy, more specifically Airborne Wind Energy (AWE), also known as High Altitude Wind Power.

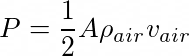

AWE is the harnessing of wind energy at altitudes usually exceeding 500 meters. One of the strongest reasons for operating these devices at such high altitudes is that generally, wind speeds increase with altitude. This is important because the theoretical maximum power (𝑃) that a windbased device can generate depends on the cross-sectional area of the device that is exposed to the wind (A), the density of the air (ρ), and wind speed (v), as shown by the following equation (3). Therefore, all other factors being held constant, by doubling the wind speed the power generated can be up to eight times as large.

Additionally, AWE devices that operate at higher altitudes experience more consistently high wind speeds and therefore spend more time producing power. This is important as all technology that harness wind power require a minimum wind speed to start producing power, known as the cut-in speed (usually between 3–4 m/s for conventional wind turbines (3)), as the generator must overcome friction and other forces.

The first detailed scientific papers hypothesizing the feasibility of AWE and its potential power density of 11.6 kW/m² operating at wind speeds of 10 m/s were published in the 1980s (4), with the first functional small-scale AWE prototypes developed in 2006 (5). To put the timescale of AWE’s progress into perspective, mature technologies such as conventional wind turbines have been commercially available as early as 1850 (6) and have largely remained unchanged in terms of design. The largest of these conventional wind turbines currently in operation in Rotterdam only reach 260 meters tall — General Electric’s Haliade-X featuring a 220-meter rotor diameter and a capacity of 12

MW (7).

AWE can be primarily categorized as to whether they generate power on the ground (ground generation) or in the air (onboard generation). They are further subdivided according to the physical structure of the device, which can take the form of a rigid or flexible kite, a tethered drone, or a lighter-than-air aerostatic system. The mechanism through which AWE generates electricity is akin to existing conventional wind turbine technology in that the kinetic energy of the wind is used to eventually drive an electrical generator thus producing electricity.

Ground generation devices generally take the form of kites that are tethered via a retractable cable, which is connected to a rotating drum and subsequently an electrical generator anchored to the ground. All kite devices operate in a pumping cycle, which consists of the cyclical reeling-in and reeling-out of the retractable cable, which consumes and generates power respectively. The optimization of the device’s flight path is usually controlled by an onboard Kite Control Unit.

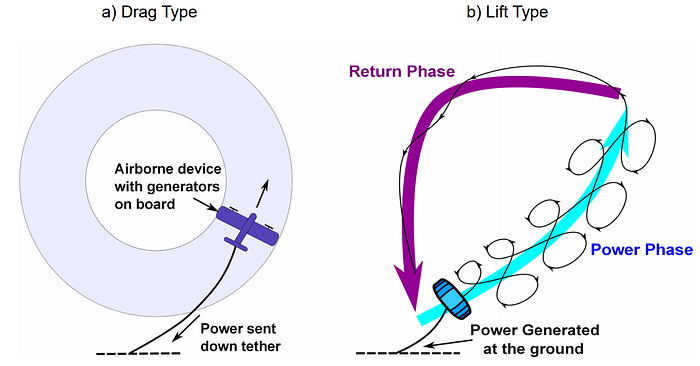

Onboard generation devices usually feature smaller turbines that are directly connected to an electrical generator housed onboard the device itself as it operates at high altitudes. The electricity produced is transferred down to the ground via a tether which doubles as an electrical transmission cable. These devices often take the form of glider frames that house rotors and generators.

Leading Technology

Out of all the AWE companies that have begun developing products, several frontrunners in the industry have been identified with the potential for progressing their prototypes into commercial solutions.

Kite Power Solutions have tested a 500-kW ground generation model with the intention of integrating multiple units into a 3 MW windfarm. Their design utilizes two kites per generator, such that during the pumping cycle the power production will be continuous as when one kite is reeled in the other kite will be extending (8).

SkySails Power, founded in 2001, already has commercial solutions for power generation in the shipping industry. SkySails have developed modular mobile units that can be housed within a 20-foot ISO container capable of generating between 200–500 kW of ground generated auxiliary power, supplementing the main diesel generators. Since 2006, SkySails Marine has utilized kite power to provide towing forces for commercial ships, resulting in increased cost savings of up to €300,000 annually due to lower fuel consumption (9).

Ampyx Power, founded in 2008, utilizes a tethered rigid kite which has a similar appearance to a glider. Their 150-kW ground generation Ampyx Power 3 (AP3) prototype is a rigid kite with a 12 m wingspan. Its successor, the AP4, is already a commercially available product which has a 150 m^2 wing surface area and has a capacity of 2 MW. Unlike its other competitors, AP3 and AP4 deploy on a short runway platform that utilizes a landing gear and a catapult-arrestor system that propels the rigid kite during takeoff. Ampyx Power has plans to expand their product line to include solutions capable of achieving a capacity of 5 MW (10).

Lastly, Makani Power, founded in 2006, has produced an airborne generation prototype (M600) with a 28-meter wingspan with a capacity of 600 kW. It is unique in that it deploys and recovers in a vertical orientation, with its rotors doubling as turbines that consume power during takeoff but start generating power when it has reached its operating altitude. Makani has plans to scale up their current prototype to a 65-meter wingspan device that can generate up to 5 MW (11).

The European Commission has conducted analysis on the maturity of AWE technology and identified tethered drone technology such as Makani Power’s as the most developed, closely followed by rigid and flexible wing technologies demonstrated by Ampyx Power, SkySails Power, and Kite Power

Solutions (12).

Energy Availability

Various sources estimate that the world currently consumes approximately 18 TW of power, equivalent to 157,680 TWh annually (13) (14) (15). While it is difficult to exactly quantify how much wind energy can be harnessed, upper estimates have placed the theoretical figure between 72 and 94.5 TW , assuming that most of the wind over oceans and land can be utilized (16) (17).

It is important to understand that the equation describing the maximum power generated is merely a theoretical number, which has not accounted for inefficiencies and losses. Similar to how the Carnot efficiency describes the maximum efficiency of a heat engine (≈ 64%), the Betz efficiency expresses the maximum efficiency at which the kinetic energy from wind can be converted into electricity using wind turbines or similar technology (≈ 59.3%). Therefore, accounting for the Betz efficiency as well as the logistical difficulties in harnessing wind energy in the deep ocean and other inaccessible areas, conservative estimates expect a minimum of 7.5 TW accessible to conventional wind turbines and AWE (18).

The United States Department of Energy has developed a classification system to rank the average annual wind speed and wind power density across the world. Class 7 represents wind speeds and wind power densities between 7.0–9.4 m/s and greater than 400 W/m2 respectively and Class 1 corresponds to 0.0–4.4 m/s and 0–100 W/m2 respectively (19). The data suggests that wind

speeds and wind consistency are better in the polar seas than the rest of the world.

Challenges and Opportunities

It is inevitable that new technology will encounter many hurdles before it ever becomes successful and widely adopted. The first of which will be obtaining the appropriate clearance to operate, as unmanned aerial devices exceeding 20 kg in weight cannot operate at altitudes exceeding 400 feet above ground without approval. It is to be expected that such regulations exist in many different countries and further complications may arise if such devices are to be operated 24/7.

A “carbon lock-in” phenomenon that exists in many countries describes the significant barriers to entry in the energy industry due to the existing economies of scale that fossil fuel companies enjoy. Without external intervention by the government or drastic shift in public demand for renewable energy, renewable energy companies in their infancy cannot stay competitive.

For AWE to be feasible in the long term, it needs to function autonomously in all weather conditions including autonomous deployment and recovery during inclement conditions. Consequently, further development is required in this area. Additionally, technical constraints arise in the materials used

for the tether in ground generation devices. In order to optimize the power generation, tether drag must be minimized by reducing the exposed cross-sectional area whilst maintaining the required tensile strength to resist the forces generated. Presently, most devices utilize high-modulus polyethylene, known as Dyneema, for their tethers which has a tensile strength of 2.4 GPa similar to steel, but weighs 8 times less. Further research into development of tethers with greater strength to weight ratios could optimize the power generated.

Despite the numerous challenges of implementing AWE devices, there are significant benefits that arise from their usage. AWE devices are generally more compact, as most of the critical electrical components are situated near the ground and some can be housed in 20-foot ISO containers. In the event of inclement weather or an earthquake, AWE devices can be recovered and shielded from the elements. This is in direct contrast to conventional wind turbines which are permanently exposed to the elements and are therefore more susceptible to structural damage or failure in bad weather,

especially when deployed offshore (20).

A strong advantage that AWE has over conventional wind turbines is that significantly fewer resources are required to manufacture, transport, and install each device. Large wind turbines such as the Haliade-X weigh over 2,550 tons and require considerable amounts of concrete and steel for its foundation (21). AWE effectively replaces the turbine blades and tower with a kite/drone device and a tether respectively, cutting down on the overall weight of the device. AWE’s mass savings are reflected in its significantly lower mass to power ratio of approximately 6 tons/MW compared to

Haliade-X’s 68.8 tons/MW (21) (22). Recent estimates have priced a 2 MW AWE unit at €1.3 million, not considering benefits from economies of scale. Similarly rated conventional wind turbines have an upfront cost of three times this amount. Operation and maintenance costs for AWE units are projected to be €10/MWh, with onshore and offshore conventional wind turbines costing

approximately two and three times the price respectively (22). It has been forecasted that by 2030, wind energy produced by AWE devices could decrease from currently €90–150/MWh to €30/MWh (23).

Perhaps AWE’s greatest strength lies in its deployment versatility and transportability. For this reason, they can be deployed extensively offshore where windspeeds are higher and more consistent, as they do not require sophisticated deep-sea substructures for support. Additionally, the use of AWE devices as an emergency power supply, in lieu of diesel generators, for disaster relief in rural areas is being explored (24).

While AWE is a relatively new technology in the early stages of development, it holds the potential to unlock a greater portion of the global wind energy resource to satisfy growing energy demands. The benefits of sustainably generating power without greenhouse gas emissions, providing power at

a lower cost, and tapping into more of the available offshore wind, highlight the gains that can be realized with further research and investment. The maturation of AWE technology could be the next evolution of wind energy and may be instrumental in tackling the climate crisis.

References

- Roser M, Ritchie H, Ortiz-Ospina E. Ourworldindata. [Online].; 2019 [cited 2020 February 9. Available from: https://ourworldindata.org/world-population-growth.

- Abbasi T, Premalatha , Abbasi SA. The return to renewables: Will it help in global warming control? Renewable and Sustainable Energy Reviews. 2011; 15(1): 891–894

- Wind Power Program. Wind Power Program. [Online].; 2016 [cited 2020 February 19. Available from: http://www.wind-power-program.com/turbine_characteristics.htm.

- Loyd ML. Crosswind Kite Power. Journal of Energy. 1980 May; 4(3): 1–6.

- Fagiano L, Milanese M, Piga D. High-Altitude Wind Power Generation. IEEE Transactions on Energy Conversion. 2010 March; 25(1): 168–180.

- Office of Energy Efficiency & Renewable Energy. Energy. [Online].; 2018 [cited 2020 February 09. Available from: https://www.energy.gov/eere/wind/history-us-wind-energy.

- General Electric. World’s Most Powerful Offshore Wind Turbine. [Online].; 2019 [cited 2020 February 9. Available from: https://www.ge.com/renewableenergy/wind-energy/offshore

wind/haliade-x-offshore-turbine. - Foxwell D. Riviera Maritime Media. [Online].; 2018 [cited 2020 February 9. Available from:

https://www.rivieramm.com/news-content-hub/consultant-sees-potentially-game-changing-role-for-airborne-offshore-wind-25753. - ShipTechnology. MS Beluga SkSails — Cargo Ship Technology. [Online].; 2018 [cited 2020 February 9. Available from: https://www.ship-technology.com/projects/msbelugaskysails/.

- Ampyx Power. Our Technology Explained. [Online].; 019 [cited 2020 February 9. Available from:

https://www.ampyxpower.com/our-technology-explained/ - Makani. Technology | Makani. [Online].; 2019 [cited 2020 February 9. Available from:

https://makanipower.com/technology/. - Directorate-General for Research and Innovation (European Commission). Study on challenges in the commercialisation of airborne wind energy systems. Brussels: European Union, European Commission; 2018. Report No.: ISBN.

- BP. BP Statistical Review of World Energy. Annual Report. , BP; 2019.

- Marvel K, Kravitz B, Caldeira K. Geophysical limits to global wind power. Nature Climate Change. 2013; 3: 118–121.

- US Energy Information Administration. International energy statistics database. [Online].; 2019 [cited 2020 February 19. Available from: https://www.eia.gov/international/data/world/total-energy/total-energy-consumption.

- Archer CL, Jacobson MZ. Evaluation of global wind power. Climate and Dynamics. 2005 June; 110(D12): 1–20.

- Murthy KSR, Rahi OP. A comprehensive review of wind resource assessment. Renewable and Sustainable Energy Reviews. 2017 May; 72: 1320–1342.

- De Lellis M, Reginatto R, Saraiva R, Trofino A. The Betz limit applied to Airborne Wind Energy. Renewable Energy. 2018 November; 127: 32–40.

- NREL. Classes of Wind Power Density. [Online].; 2007 [cited 2020 February 9. Available from: https://www.nrc.gov/docs/ML0720/ML072040340.pdf.

- Langley W. Go, Fly a Kite: The Promises (and Perils) of Airborne Wind-Energy Systems. Texas Law Review. 2015 December; 94(2): 425–450.

- de Vries E. Wind Power Monthly. [Online].; 2019 [cited 2020 February 19. Available from: https://www.windpoweroffshore.com/article/1577816/haliade-x-uncovered-ge-aims-14mw.

- KiteGen. KiteGen. [Online].; 2016 [cited 2020 February 19. Available from: http://www.kitegen.com/pdf/KiteGen%20Presentation%20ENG_mar2016.pdf.

- Mann S. Catapult. [Online].; 2019 [cited 2020 February 19. Available from: https://s3-eu-west1.amazonaws.com/media.newore.catapult/app/uploads/2019/02/21165944/An-Introduction

to-Airborne-Wind-Stephanie-Mann-AP0020.pdf. - Das R. Electric Vehicles Research. [Online].; 2017 [cited 2020 February 19. Available from: https://www.electricvehiclesresearch.com/articles/10700/kite-power-diesel-killer-or-wind-turbine-killer

- Mann S, Gunn K, Harrison G, Beare B, Lazakis I. Wind Yield Assessment for Airborne Wind Energy. In EWEA Offshore 2015; 2015; Copenhagen. p. 1.

- Chong WZ, Chong YL, Jing P, Ming YL, Lin LX. An overview of global ocean wind energy resource evaluations. Renewable and Sustainable Energy Reviews. 2016 January; 53: 1240–1251.